|

In our quest to get off the grid we ran into a few possibilities of how we can do this: solar, wind, hydro, internal

combustion generator, or no power at all. Well obviously the latter isn't an option for us 21st century folks, well

not totally. Anyhoo, hydro ain't an option since we're not near a moving stream. Wind isn't an option since we're

not in a good wind zone. So that leaves solar and IC power. Now solar is definately going into the mix, but due

to the cost of solar panels, its something thats going to have to be built up a little at a time. Even then, unless

we custom tailor our energy use to be low enough that a small solar array would be enough to run most of everything and recharge

the batteries, we're going to have to have something else to help take up the slack when the sun sets and the batteries are

still yearning for juice. This is where the diesel generator comes in.

I chose a diesel generator for several reasons. A gasoline generator uses more fuel to produce the same power that

a diesel engine can. Gas engines don't last as long as diesel engines. And there's one thing a diesel can do that

a gas engine can't, thats run on vegetable oil! The goal of this project is to make a generator that can run on waste

veggie oil thats stored in bulk in a hopper. The oil will obviously be acquired from restaurants.

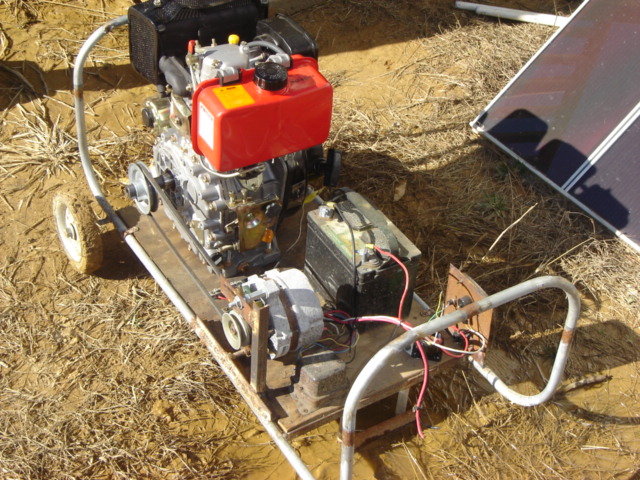

The generator has its history however. The generator had already been made a while back when I was back in IL using

a gas engine and Ford alternator I had. I made the thing using conduit and angle iron to make the frame. A single

axle with a couple of lawn mower wheels helped make the unit portable. A tube and angle iron foot helped keep the unit

level. A board on the bottom of the frame held the engine and alternator along with the voltage regulator and terminal

blocks while a top board held a power inverter. The top portion of the frame had two 4-outlet boxes welded to it along

with a piece of plate steel that held two voltmeters and finally two 12v receptacles were welded between the voltmeters

and outlets along the top of the conduit.

|

| The generator in its original form |

Now the first thing that I did was remove the gasoline engine, but in order to bolt down the bulkier diesel engine, I

had to remove the top of the framing, which included the board with the inverter and the angle iron that held the outlets

and voltmeters. After dispatching the unnecessary material, I bolted the diesel down and hooked up the belt. I

had to get a pulley from grainger since no one had a pulley for a 1" shaft. Anyway, since the voltmeters were a vital

part of the whole system, I had to keep them, so I re-welded the plate holding the meters on the bottom part of the framing.

The solenoid that was used to switch the alternator output to the storage battery was also relocated from the top board down

to the bottom board right behind the voltmeter panel.

|

| Modified generator with diesel engine and vital components relocated where there's space. |

Well after playing around with the generator a few times, I uncovered a few flaws that had to be addressed before this

thing can be pressed into service. For one, the board isn't really any match for the torque crazy diesel engine.

As the engine rotates, the board buckles in the middle where there is no extra support. This also isn't good for the

belt which bops all over and acts like it wants to come off, which is another flaw, the grooved mounting point that acts as

a tension adjustment for the alternator and belt. Then last but not least was the idea that the old frame was actually

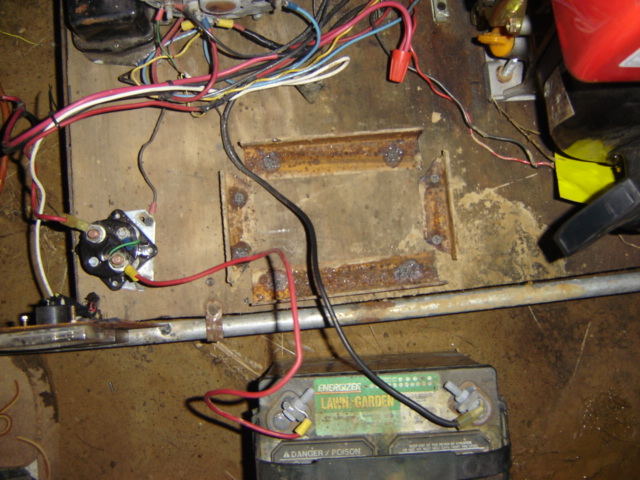

a little larger than need be for the hardware thats installed. Lastly, the battery needed some kind of cradle to keep

it from vibrating off the board. To address this I first took some conduit brackets and screwed them in place in the

middle of the frame on either side to hold the board, we'll see how well this works. To address the battery cradle issue,

I cut four pieces of angle iron and screwed them in place in the area where the battery goes to cradle the battery and keep

it from vibrating off the board.

|

| Battery cradle in place; note new location of voltmeter panel and solenoid, both at bottom left. |

To address the size issue, I cut the conduit frame that was opposite of the diesel engine and trimmed off some of the

excess pipe then re-welded the U-shaped section of conduit frame back to the generator frame, hereby shortening the length

of the overall generator machine. I also relocated the voltage regulator alongside the solenoid instead of next to the

alternator so I can give the alternator more room for travel when it comes to adjusting the tension on the belt. I also

trimmed some of the wires down and reattached them to neaten up the overall batch of wiring. Since the engine has a

starter motor, I also welded on a plate steel panel that now holds the starter switch, which is located on the frame behind

the diesel engine.

|

| Pic of super modified generator with shortened framework, note starter switch by engine |

During the times that I did run this thing i did learn some stuff. For one, the output of the alternator acts much

like a solar panel. When its metered on an open circuit, the voltage, even with field coil regulation via the Ford voltage

regulator, still read 33V. When I hooked up the storage battery to the output, the voltage dropped to 14v. When

I tried powering the field coils right off of 12v, the output voltage on open circuit was 66V, a little too much! Also,

I found that the diesel engine has this voltage generator module on the engine that is used t recharge the starter battery

under normal use. I used this thing to provide the power for the alternator's field coils, as well as serve as a means

to recharge the battery. This essentially allows me to do away with the storage battery all together, especially since

this generator is going to be used to recharge a battery bank in the house power system. The 33V open circuit power

should be ok since the voltage does drop when the battery is hooked up. I will still use the storage battery since I

plan on hooking up the starter motor but the voltage generator on the engine is going to be the primary voltage source for

the alternator.

I omitted the inverter and outlets and all of that other hardware since this generator is going to be nothing but a raw

source of battery recharging power for a large battery bank. When we build our power shed, which will house all the

electrical hardware that will make up the house's power supply, this generator will be set up inside and hooked up to the

battery bank to supply power for the battery bank whenever the batteries get low during dark hours, or when a heavy load is

brought into service on the system. By doing it this way, whenever a heavy load is used, the generator will help keep

the batteries from being depleted too fast, while under normal circumstances just allowing the batteries to take juice when

the sun dont shine.

My first steps towards running this thing on veggie oil will be when I set up my bio-fuel processor, which is a simple

mixing and filtering set up that is going to be made mostly from plans I bought from a guy on ebay. I did make a few

modifications to the design of the processor to better suit me, but the main thing in the plans that I was after was the formula

for the fuel mixture. The mixture uses mostly veggie oil, with other common fuels as mere additives to help make the

overall fuel have the same consistency as diesel fuel without having to do any modifications to the little diesel engine.

If the tests work (after I make some bio-fuel), then I will go ahead and try the same setup on our F350 diesel truck.

Coupled with the diesel engine's natural ability to make power by merely sipping fuel instead of drinking it down like

a spark engine, using veggie oil as the primary fuel would allow me to recharge the battery bank for nearly nothing, with

the exception for a few cents work to process the fuel.

I managed to get the starter system hooked up to allow for effortless starting of the diesel engine. I used some

4 ga cable to go from the starter to the battery and for the ground from the engine back to the battery. I used a single

wire to feed positive power to the switch, which the circuit was then completed with another short wire from the switch to

the solenoid on the starter. Everything was wire tied to keep everything nice and neat. The starter will crank

the engine over effortlessly, even without the decompression lever activated. This will allow for even the most frail person

to start the generator, or make for worry free starting when starting on veggie oil based fuels.

|

| Cables run for starter system on diesel engine, both cables are black. |

Another final addition to the generator I made was the addition of a turnbuckle to act as a tensioner to hold the alternator

tight against the drivebelt in the event the bolt loosens up on the tensioning track. I had to weld a piece of flat

steel from my scrap pile onto the generator's old framework to provide for a solid place to hook the other side of the turnbuckle.

The flat steel had a 3/8" bolt already welded to it, apparently from some project I long since abandoned. I was then

able to hook the turnbuckle to that bolt and the other end to the top mounting bolt of the alternator to give it a nice and

solid tensioning against the drive belt. I let the thing run a good while during my cleanup period and everything ran

well. Of course that was when the generator wasn't under load, that will be the generator's true test of durability,

running it under real world conditions. Worst case I might have to replace the drivebelt since it is an old belt.

Updates on this project soon to come...

|

| Turnbuckle tensioner to hold alternator tight against belt, note steel bar to left of turnbuckle. |

Over New Year's day, I decided to try a little something. I made up a vegetable oil based fuel mixture based on

a formula that was in a manual for assembling a bio-fuel processor that I bought off of EBay (I bought the manual, not the

processor itself). I took a 1 liter bottle and poured in 75% SVO (not WVO, this was pure oil), 15% kerosene, 8% gasoline

and 2% diesel fuel additive. I shook all this stuff up real good to get it all blended well then poured the contents

into the diesel's fuel tank. I went ahead and pulled the cord (the battery was too low to use the starter) and the engine

started up. After a minute the veggie oil blend finally made its way into the engine's fuel system and the aroma of

burning veggie oil was noticable in the air. I know that there are a lot of people that have successfully and are still

successfully running diesels of all walks of life on veggie oil but this is a thrill to personally be able to say I ran one

of my engines on veggie oil! The engine ran real good for an hour before running out. I guess a liter of fuel

lasting an hour at full throttle while recharging a marine battery is real good. Well when the fuel ran out, I mixed

a new batch and poured more in the fuel tank, leaving a little in the bottle for a test. I ran the engine some more

before finally shutting down to store it.

The following night the temps dipped down near freezing. The bio-fuel in the bottle still remained liquid.

The following morning I pulled the generator back out to start again. I had to pull the cord two times before it finally

sputtered to life. Not bad for having mostly VO in the fuel lines and being dead cold. Alright, that test was

good. Next night, the temps dipped well below freezing, about 19 to be exact. Well needless to say the sample

fuel in the bottle was thickening, but not totally solidified. The WVO we had in some jugs was all solid by now, thanks

to the animal fat in the oil. Well the following morning, once the sun came out and the temps started to increase, the

bio-fuel in the bottle thinned back out to a more liquid form once again. I pulled the generator out again to start

up. This time it took four good pulls of the cord before the engine finally sputtered to life. Afterward the engine

smoothed out and ran flawlessly, until it ran out of fuel.

Now my next thing will be to filter some of the WVO we have and blend it based on the formula in that manual so we can

make a larger batch of bio-fuel to try in the generator. This will be the ultimate test, since this is with WVO that

has animal fat mixed in it (among other things). Obviously the filters will take care of the fat and other thick crap

but still, this isn't virgin oil. Once I set up a processor, I can start processing some oil to try out in the generator.

If its successful (which it should be), then I can move ahead another step and test some of this crap in the F350.

Updates:

Well its been a while since the last entry into the diesel generator log, and a lot has happened since then. For

one, we've been running this thing on filtered veggie diesel courtesy of our recently made veggie diesel processor machine,

which allowed us to produce veggie diesel in 5 gallon increments. But like always in the ways of the Improvisation Center,

we never settle for anything staying as it is and always find ways to make something better, and the diesel generator is no

exception.

Since the generator was limited in its use (basically an oversized battery charger), we figured that the next best thing

to do to this device is to remove the car alternator and its associated hardware and replace it with a standard generator

head. This way, we can still recharge batteries using a standard battery charger, while at the same time doubling as

a power supply in and of itself.

In comes the 5kw generator head. This shaft driven generator head was picked up off of Ebay for a couple hundred

bucks and has two onboard outlets and a power cable for hard wiring into a breaker box.

After stripping everything off of the generator platform, including some welded on hardware, I did some measuring and

managed to drill the three holes needed to mount the generator head to the platform. I also took a jigsaw to elongate

the holes to allow for adjusting the gen-head for belt tension.

|

| 5kw generator head purchased from Ebay for the upgrade |

|

| Generator platform stripped down of everything but the engine |

At this point we had to acquire a pulley to fit on the shaft of the gen-head so we can move onto the next phase in the

upgrade. After that, I took the gen-head and bolted it down to the platform while at the same time putting the belt

on and adjusting for the most tension as possible. At this point that is all that had to be done. Of course since

there was no room for a battery on the generator platform, so in order to start I had to use the pull cord.

Surprisingly, upon starting, after sitting for a good couple of months with veggie diesel sitting in the lines, that

engine fired up in the first pull of the cord (nevermind the temps were in the high 60's). After starting the engine,

I plugged the drill up to the gen-head, it ran just fine. Then I decided to do a real big test. I plugged up our

air compressor to the gen-head. Lo and behold, the air compressor fired up and ran at full speed. Nevermind that

the engine did show some drag indicating that the gen-head was putting out big time. And put out it did, for it to put

out the 30+amps that the motor initially drew upon startup along with the 15 amps continuous output to run the compressor.

The belt was tight enough that the pulley didn't slip, plus the gearing ratio was good enough to allow these devices to run

pretty well. Obviously the next level of tests will be the testing of some electronics on the generator.

This generator, as stated before, will be used for double duty. It will be hooked into our off grid house power

system by being hooked into the breakers that will run the heavy loads (washing machine, compressor, etc), while having a

heavy duty automotive battery charger hooked up to deliver the 40+ amps to charge the bank of batteries in a short amount

of time. We may even have a couple of breakers hooked up with a standard transfer switch so if necessary we can switch

some loads to the generator as a contingency plan - total redundancy, especially for a pieced together po' man's off grid

power system.

9-18-10:

Over a year ago the engine on the diesel generator crapped out after getting a hold of some bad veggie fuel we made that

was used when the weather was too cool. After a couple of attempts at trying to start the thing I ended up setting the

thing aside for that time. A week ago I pulled the engine to the side and pulled the injector and fuel pump and soaked

them in parts cleaner and managed to get the engine to start back up again.

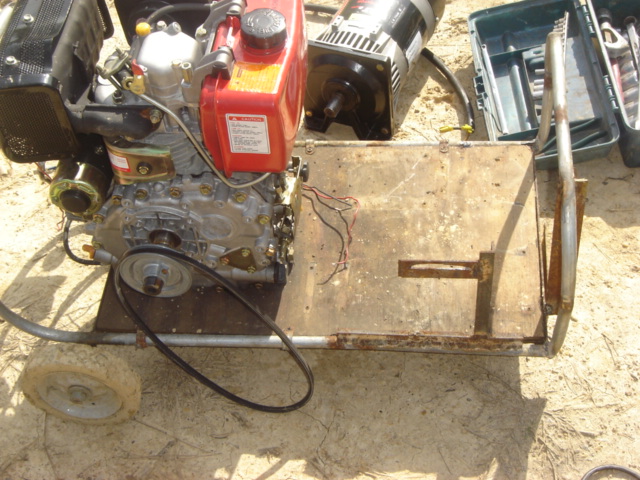

The frame and body of the generator were from the very start weak designs using scrap parts not really intended for this

type of duty; the conduit frame had cracked and the board would flex with each cycle of the engine. I decided to rebuild

the generator.

We had a complete bed frame that we received from a friend who was moving and was going to throw the thing away anyway.

This would be the basis of the generator. With some cutting and welding I fabricated a framework with the holes, many

which were already there, lined up in the right places to mount the engine and generator head. I welded the axle and

stand on, along with a tow handle which was actually a section of conduit from the old frame.

I even welded a couple of pieces of angle iron to accomodate a battery in the remaining space on the other side of the

generator head. With that, the generator was ready to rock and roll.

Granted the battery was on the verge of being shot anyway, and near as I could discover, was low on water, as soon as

the engine cranked to life with the aid of our jump starter set at 40 amps, the filler caps to the battery blew off.

Luckily I wasn't close enough to get any acid sprayed on me but for all intents, this battery might be shot, I don't know,

I will have to put some water in the thing and see if I can resurrect it. That's the 2nd time I blew a battery up.

But nonetheless, the generator was a success, its got a new chassis and runs like a champ. As you can see from the pictures

of the blackened area where the engine's exhaust blew soot all over the ground, the engine ran well for a while.

We will probably try to bring back the veggie diesel goals once again, but this time, try to do things right enough that

the engine won't have any problems like the last time. Only time will tell.

|

| The new and improved generator complete with soot |

|

| Another shot of generator, zoom in to see details |

|